In Time and On Budget: How Neural Networks Can Solve Inventory Problems

Imagine you are running a cake factory. One of your key inputs is flour, which you use in large quantities, so you need to order more flour pretty regularly. It’s hard to predict exactly how many you should order, though, since your cake orders can vary significantly. In a slow month, a steady weekly delivery of flour might work well, but at a busy time – maybe before Christmas – you may need to place a few rush orders to keep the production lines running and ensure customers aren’t disappointed.

Of course rush orders are expensive. You don’t want to plan on too many of those. On the other hand, stockpiling flour to avoid that rush delivery fee means extra warehousing costs, and possibly waste (flour has a limited shelf life!). And of course running short of supplies carries the risk of production outages and lost customers. It’s a very tricky balance.

This issue – known as dual sourcing problems, where “dual sourcing” refers to the two delivery options (slow but affordable, or fast and expensive) – is of course old and rather prosaic. But in recent years, mathematicians have been working on new solutions, resulting in impressive efficiency improvements in just 15 years; and now, machine learning is driving even closer to an optimum result.

Reducing the gap

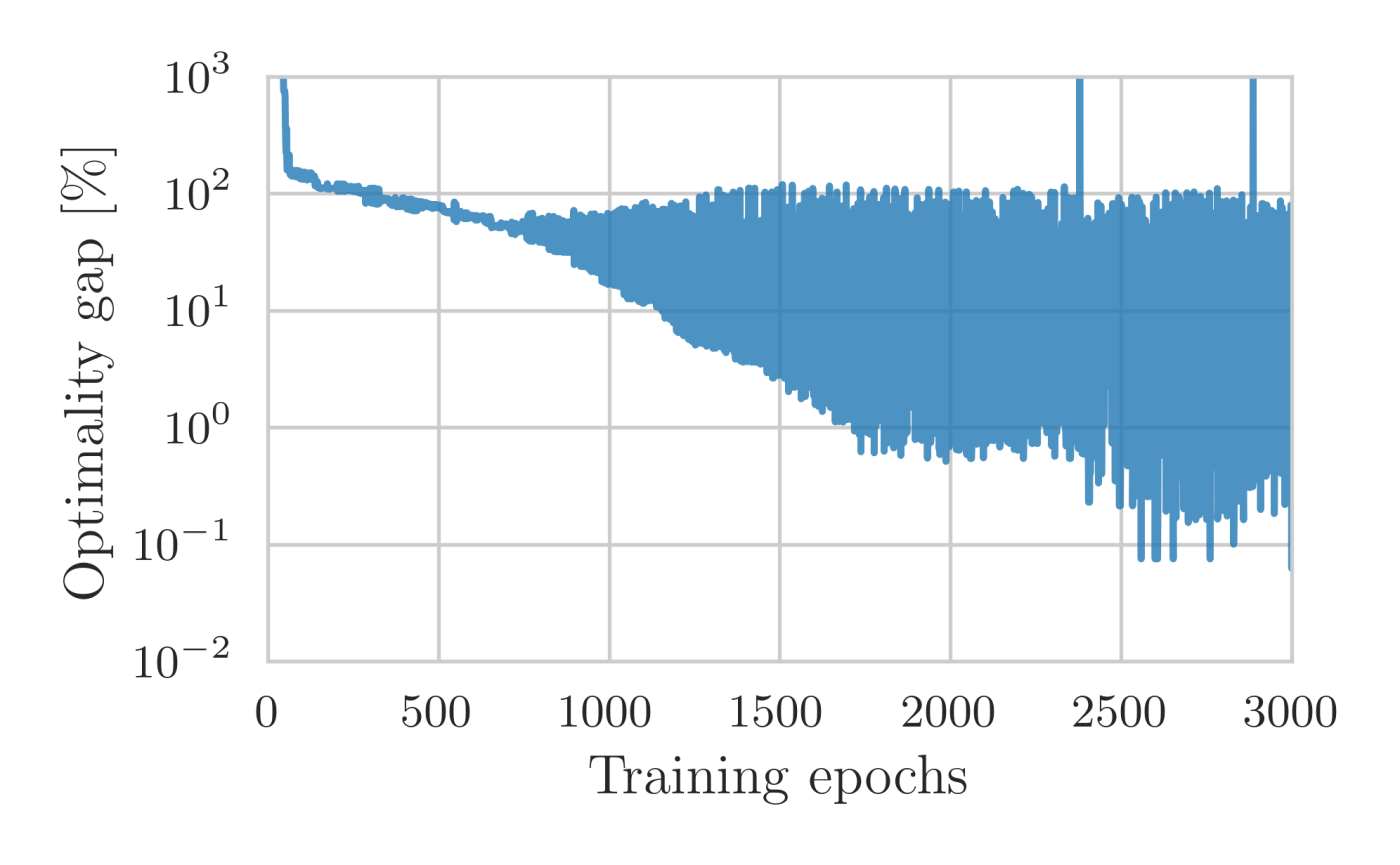

Inventory sourcing problems are a specific subset of problems in optimal control – a mathematical field pioneered by Lew Pontrjagin and Richard Bellman in the mid-20th century (and used in planning the Apollo moon missions). Back in 2007, the state of the dual sourcing art was the “single index” heuristic, which allowed for inventory management with an “optimality gap” (meaning the difference between actual and optimum costs) of about 10-20%. But the next year, the “dual index” approach cut that gap down to about 1-2%.

Of course, this gap is an academic calculation and cannot usually be determined accurately in the real world. It is nonetheless a useful indication of the scale of inefficiency in the system. And in 2019, after a decade of further investigations of the dual index breakthrough, this gap was trimmed to as low as 0.5-1% with the “capped dual index” method. That’s a huge improvement, but there’s still money on the table: how can we scrape away that last bit of waste in the system? How can we get to the best possible system for efficient inventory ordering?

In this surprisingly busy research field, a new approach has emerged that leverages recurrent neural networks’ capacity to learn and improve. This solution, devised by a cross-European research team comprising the NCCR Automation’s Thomas Asikis (from Game Theory, University of Zurich), along with Lucas Böttcher (Frankfurt School of Finance & Management and University of Florida) and Ioannis Fragkos (Rotterdam School of Management Erasmus University Rotterdam), uses a dynamics-informed neural network to calculate possible order schedules and associated costs, taking into account a wide array of inputs.

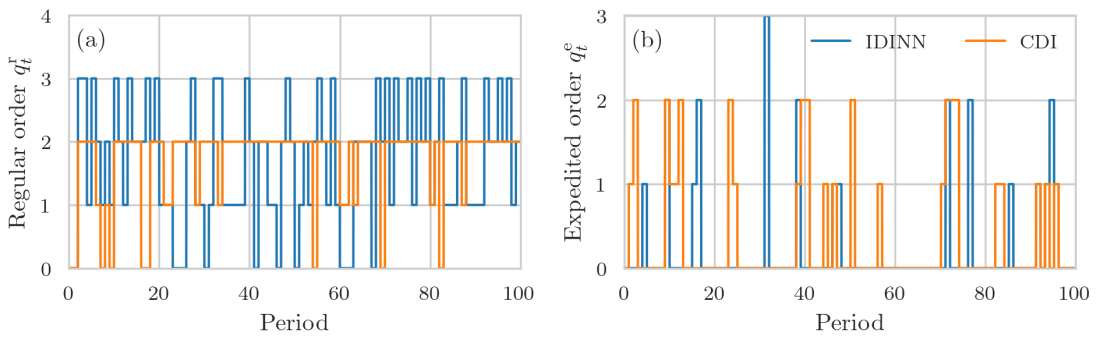

The results are impressive. After just a few minutes of training on a regular personal computer, the neural network can achieve substantially smaller optimality gaps than are possible using the standard “capped dual index” calculations. Across a large number of instances studied by the authors, the neural network either outperformed the capped dual index policy or achieved equal performance. Additionally, they demonstrated that their method can be seamlessly integrated with actual demand data, effectively addressing the challenge of learning optimal order policies in real-world supply scenarios.

Key to this breakthrough is the “dynamics-informed” element. This means that the neural network is designed to take into account how the system being optimized behaves over time. The design also leverages existing knowledge of the structure of optimal solutions – the neurons within the network resemble established “good ways” to place orders, so the network is building on already good practice. The result? Lower costs, but also less waste and better customer satisfaction – benefiting consumers and the environment, as well as the factory.

While the inventory problem is a very concrete example that shows great practical gains, the usefulness of this approach goes beyond logistics. This neural network design can achieve better results than traditional methods developed in operations research and optimal control, with just a few minutes of computation time. The process of designing these networks can be effectively applied to any complex system for which we have models that capture its evolution over time, solving problems in transport and healthcare, for instance. In particular, the emergence of medical digital twins (computational models simulating biomedical systems) holds great promise for advancing treatment and drug development. This is accomplished through the integration of computational patient models with effective neural network controllers.

Solving the dual sourcing inventory control problem is a beautiful illustration of the power of machine learning – despite intensive research efforts in recent years, computational methods were struggling to make further improvements. But improvements are still possible, as shown by this dynamics-informed neural network. It’s exciting to think how many other tricky problems may yield to similar approaches in the coming years.

Text: Robynn Weldon

Further Information:

L. Böttcher, T. Asikis, and I. Fragkos, “Control of Dual-Sourcing Inventory Systems Using Recurrent Neural Networks,” INFORMS Journal on Computing, vol. 35, no. 6, pp. 1308–1328, Nov. 2023, doi: 10.1287/ijoc.2022.0136.

For enquires please contact Linda Seward