Let’s work together: How industry and academia can join up to drive sustainability

How can we realise the potential of automatic control to unlock the next generation of technologies for our communities? It’s clear that huge advances are hovering on the horizon, with major implications for everyday domains from mobility to manufacturing. But there is still too big a gap between fundamental research and industry practice.

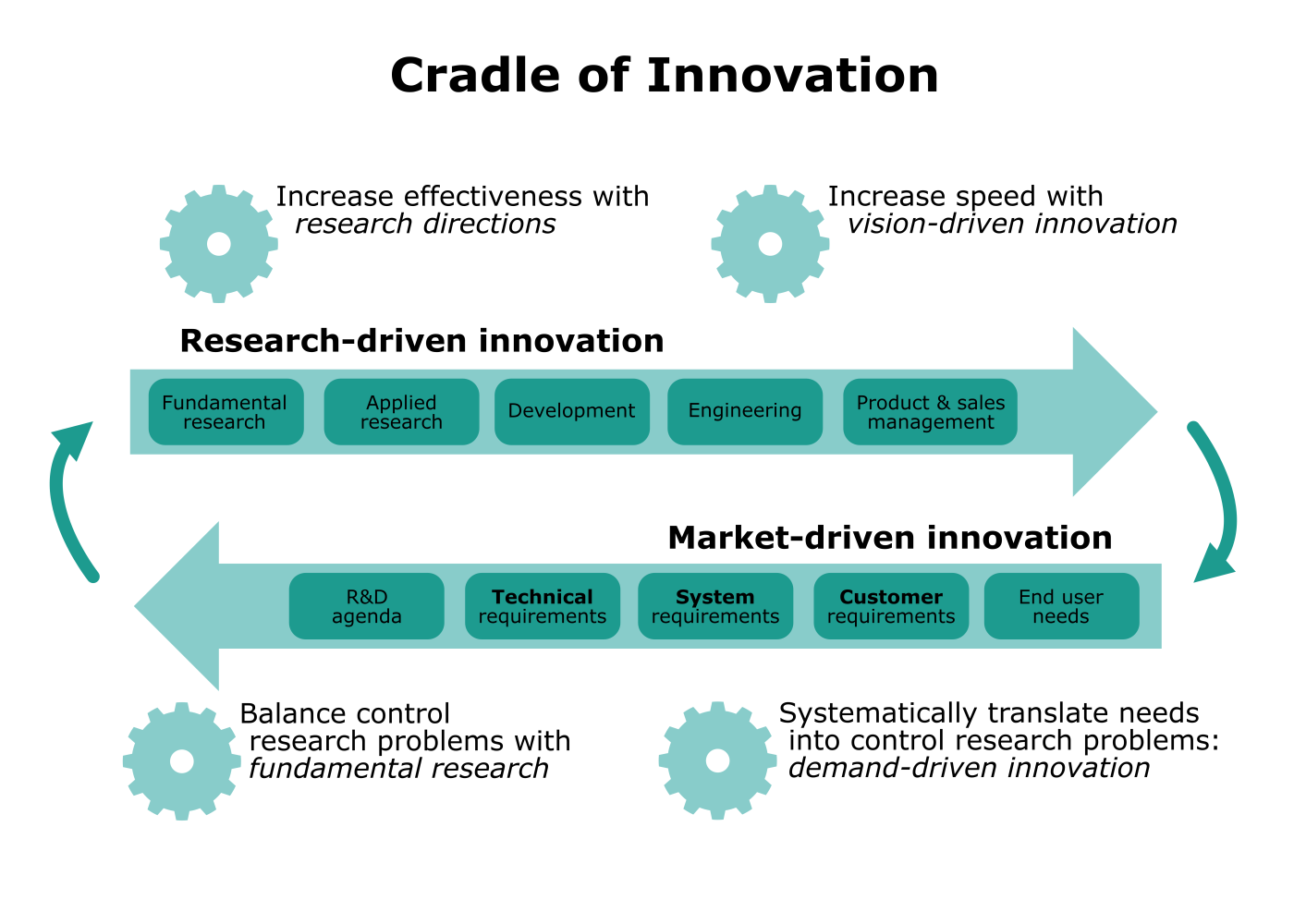

This is the problem that drove NCCR Automation researcher Silvia Mastellone, working with Alex van Delft (whose career straddles industrial management as well as research), to compile the book The Impact of Automatic Control Research on Industrial Innovation: Enabling a Sustainable Future. The idea came out of a task force within the International Federation of Automatic Control (IFAC), created to bring together academia and industry, and was developed in two directions. First, toward a defined applied research agenda to guide investigators to meet the real-world needs that can drive a great leap toward innovation and sustainability. And second, toward a proposed methodology (the “cradle of innovation”) to enable great ideas to be put into practice, and formulate research questions guided by specific technological requirements.

Same interests, different motivations

Automation researchers are passionately engaged with finding new solutions to scientific and technical challenges. The same challenges confront engineers and managers in industrial setups, where innovation is fundamental. But the drivers of these two situations are quite different. Where scientists may follow their inspiration (and disruptive ideas) over a long timescale, in business, the improvements are often incremental, numbers-driven and geared towards short-term solutions.

In their book, Silvia and Alex lay out a model they term the “cradle of innovation”, a framework for the actual innovation process that draws from both sides. The recommendation for researchers, whose work starts from fundamental research and moves towards application, is to use approaches like design thinking or agile methodologies in order to accelerate results and give focus to their explorations. For industry, where innovation starts with end user needs and drives toward research goals, the advice is to systematically translate customer demands to research problems.

Where can we get from here?

Taking this perspective – innovation for the real world, fuelled by big-picture curiosity – we can hope to accelerate transformation. The book examines advances in data infrastructure, mobility, manufacturing, power conversion and more, pointing to future directions for automation and suggesting ways in which industry can go beyond what they are already doing.

Digital twins provide a great example. The idea has caught the imagination of professionals in fields as diverse as construction and biology, and really proved its worth in space shuttle engineering. A digital twin isn’t just a model: it replicates the exact condition of a specific real-world asset. Every event, every use of the asset is recorded to the twin. So, using digital twins provides a great way to assess flyability after missions, especially given the extended lifespans and increased demands on the next generation of spacecraft. Every detail of that specific vehicle’s history can be incorporated and used to track its current state – which parts may be under stress, needing replacement or reinforcement, and so on. That eliminates the guesswork, reducing costs and improving safety.

This is a case where a concrete problem faced within an industry sparked thriving research questions in the academic world. Digital twins nowadays are employed in a wide variety of manufacturing processes, opening the new industrial revolution (what is known as Industry 4.0). In Switzerland, for example, it is common to find relatively small operations that are outfitted with legacy equipment, undergoing slow modernisation, even as they churn out highly innovative products. And this opens exciting new directions for investigation, as explored in the chapter on “Robotics and Manufacturing Automation”, contributed by the NCCR Automation researchers Alisa Rupenyan and Efe Balta. As they describe, in a field that is so concrete, research becomes excitingly experimental – one can work directly with machines, not just theory, and get very tangible results.

Similarly, the power conversion devices at the core of industrial processes, electro-mobility and energy systems are traditional technologies facing a new set of operational challenges. Researchers can find inspiration in these applications, with their rich potential for impactful innovation in the field of automatic control. Interconnecting the electrical and mechanical world, the operation of these devices is challenged by the uncertain and dynamic nature of both grid and process, as well as by the new requirements introduced by changing power generation technologies.

Of course the current energy transition also comes with added complexity, as renewables introduce a host of uncertainties. At the same time as the grid is becoming more data-driven, the mechanical processes are more sophisticated and demanding. And as the standard components evolve (such as silicon carbide replacing silicon in semiconductor switches), these devices become faster and more efficient – and they host huge potential for improving the efficiency, reliability and performance of mobility, energy and production systems. If we consider the second half of the cradle of innovation, this points to industry’s responsibility to translate contingent needs to broader research problems: the immediate pressures created by this energy transition can be leveraged to far greater impact, across multiple domains.

Bridging the divide drives progress

All these examples are interdisciplinary by nature, pointing to the importance of collaboration. Silvia talks of the “NCCR effect” in birthing this book: it’s thanks to the NCCR Automation that the co-authors were brought together. “The NCCR Automation creates a microcosmos where researchers from interdisciplinary backgrounds come together to enable a common vision of driving innovation for a sustainable future,” she says.

The next step? Silvia and her collaborators plan to run tutorial sessions at control conferences to present their results and encourage researchers to look for opportunities to get their ideas into the real world. This campaign started at the European Control Conference in Stockholm in June 2024 (see video embedded below), and a session at the IEEE Conference on Automation Science and Engineering is planned next. The industry workshops that commonly form part of conferences (and are sometimes run by the NCCR Automation) are also vital to forming concrete links between the two sides, building that cradle of innovation and encouraging entrepreneurial activities that bring research out of the lab.

Scientists pursuing big ideas have the time to explore a path without knowing exactly where it may lead. Industry has concrete goals and a more structured approach to research. Working together, the big picture can inform pursuit of more urgent solutions and drive practical innovation that is truly transformational. To read more about all the possibilities, order your copy here.